Purchase Order Processing case study

Purchase Order Processing case study

Exponent: engineering and scientific consulting

Exponent is an international engineering and scientific consulting company with 25 offices worldwide. Their engineers and scientists have worked on many high profile incidents.

“Exponent has been using Vision since 2007. We found that though the majority of the company was not purchasing intense, there were several groups that were, and each had their own process. It was time to unify and standardise the process. In FMIS, Exponent found a system that provided the flexibility we needed to accommodate our approval matrixes while still seamlessly interacting and taking advantage of the capabilities of Vision.”

Flexible approvals

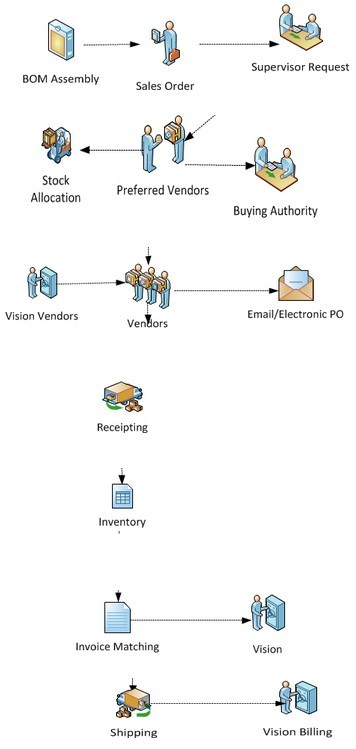

Because Exponent staff are involved in a diverse range of projects, they needed a comprehensive but flexible purchase order processing (POP) software system. Their requirements included access to an approval process that allows their requisition orders to be signed off by the appropriate staff in line with their individual approval limits and project association, before the purchase orders are automatically generated.

Deltek Vision integration

Because Exponent already used Deltek Vision, they needed purchase order processing software that linked directly with their existing system. All FMIS products including Purchase Order Processing are designed to integrate directly with the Vision software. FMIS Purchase Order Processing will automatically match purchase orders against the relevant invoice, with any amends flagged for approval before posting to the general ledger in Vision.

Established name

When considering suppliers, Exponent wanted to be confident that their chosen provider had the experience and stability to provide the level of service required over the long term. FMIS software is used in over 40 countries worldwide and has been leading the industry for over 30 years, thus Exponent was able to call industry leading clients, such as Transammonia as a reference.

For more information on FMIS Purchase Order Processing and other products, please see our product pages or contact one of the team directly at sales@fmis.co.uk or on +44 (0) 1227 773003.