Lean asset management

Why manufacturing works back to front

It is seldom a good idea to write an article that contradicts a senior colleague, especially when that colleague has several decades more experience than you, but stick with me.

In his article “Assets in Wonderland”, Mike Clements quotes Lewis Carroll’s classic line “begin at the beginning and go on til the end: then stop”. His point is valid in that asset management projects often suffer from a lack of strategic planning, however lean asset management in manufacturing requires a different approach. Start at the end and work back.

Keep it lean

Taiichi Ohno, former Toyota Chief Engineer and the father of lean manufacturing, identified seven wastes:

- Overproduction

- Transportation

- Inventory or storage

- Inappropriate processing

- Waiting

- Unnecessary motion

- Defects or Correction

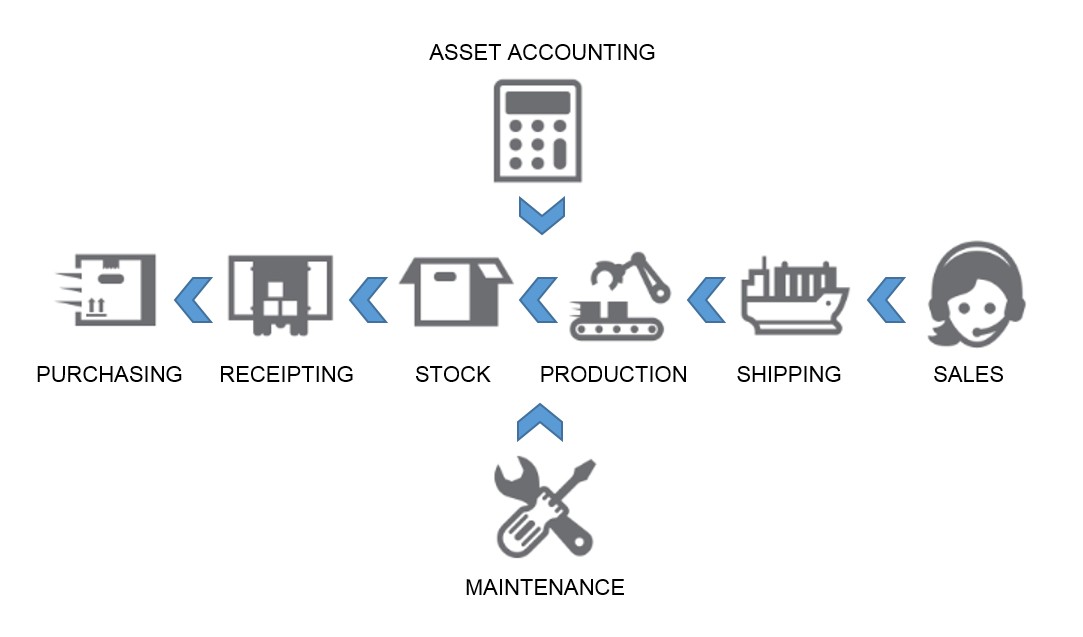

The key to lean asset management and minimising this waste is to understand the driver for each individual company. In manufacturing, more often than not, this will be the sales order. The sales order drives distribution, distribution drives production, production drives stock and inventory, which in turn drives purchasing.

Overproduction

The manufacture of products in advance or in excess of demand wastes money, time and space. You need look no further than General Motors to prove this point. Carrying almost double the industry standard of finished stock eventually lead to its collapse.

Bespoke production is relatively easy, because production tends to be in response to a specific demand. With bulk production, demand forecasting is likely to be more analytical than responsive. Clear and accurate reporting is the key to understanding previous demand and, at least in part, it is about looking back to look forward.

Transportation

When Henry Ford created the production line, it was revolutionary, but relatively straightforward as well. One stock delivery point, one production line and one distribution centre. Modern manufacturing is less clean.

Multiple sites, suppliers and contractors across different continents is normal. Knowing where inventory is located, down to a specific bin, and whether it is required for another project or whether there is an equivalent available elsewhere is essential to reducing time wasted.

Inventory

With bespoke manufacturing the key is to know early on what inventory is required for a project, so it is important that your sales order processing links directly to your stock and inventory allowing purchase orders to be raised or stock to be issued.

In the case of bulk production, you are relying on forecasts so there will always be a margin for error. Taiichi Ohno’s whole model is built on doing everything just in time. For inventory this requires three things:

- A clear understanding of what inventory is required

- Real time visibility of what is available and what is already committed

- Streamlined replenishment process

Inefficient or disjointed processes will always cause delay and at best excess inventory or at worst idle resource. Integration is the key to efficiency, multiple systems will mean delays and a greater potential for error.

Inappropriate processing

The right tools for the right job. Knowing what tools are available for each job is the minimum required. A clear view of all tools, active projects and planned commitments will allow greater flexibility to tailor and amend production schedules to match changing requirements and priorities.

Waiting

Despite what we might like to believe, people cannot multi-task effectively. We waste time waiting for one process to begin while another finishes. It is inefficient, but humans are programmed to think in a linear way A⇒B⇒C, thankfully software is not.

Lean asset management requires the ability to balance multiple projects at the same time to optimise output.

Unnecessary motion

Lean manufacturing is about cutting waste and even a single movement repeated hundreds of times if not required can represent hours wasted. Although ergonomics is not usually within the remit of pure asset management, health and safety should be.

Planning maintenance and safety checks is important, but often seems more of an irritation, distracting operations managers from the real job of getting products off the floor to time and at cost. A good asset management or CMMS system allows you to automate reminders, record results and ideally to store copies of key documents (such as inspection reports) against each piece of equipment.

Defects or Correction

Toyota famously gave each employee the power to stop the whole production line whenever a fault was identified. This revolutionary change meant that while Toyota could produce a car from start to finish in 17 hours on average, BMW spent longer than that just fixing the defects not corrected during manufacturing.

Lean asset management goes one step further by minimising the number of defects that occur in the first place. Effective scheduled maintenance and asset life cycle management will help to cut downtime and defects.